We began the day with a dense fog. Most of the day was overcast and relatively cool, getting up into the mid-70’s. After another wonderful devotional and prayer, we got our assignments.

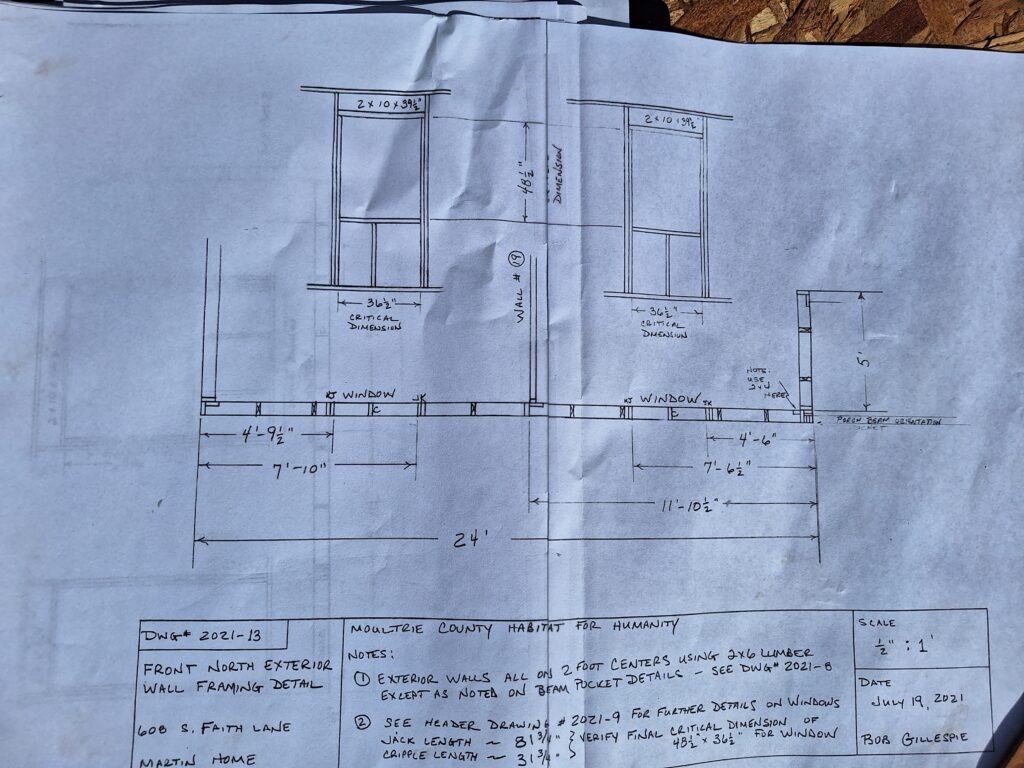

In previous years, our two week goal is to dry-in the house. We are almost there, but we need to wait for the windows to be delivered. While we’re waiting, we can get a head start on some of the interior framing items that need to be done. Our job was to cut and install a nailing surface for the ceiling sheetrock. We used a 6 inch strip of OSB to create a ledge on all walls that run perpendicular to the trusses.

Now this is working together (yes, I know you’re not supposed to be on both sides of the ladder…lol).

While we were busy inside, the roofing crew was working hard at sheeting and covering the East side of the house. It looks great!

Some vendors were busy working on some outside items:

a crew brought in a backhoe to dig a channel for the sewer line

while another crew poured the concrete for the front porch and back step.

With freshly poured concrete, we had to find an alternate way to get in and out of the house after lunch. Our Habitat beatitude comes in handy: Blessed are the flexible, for they shall not be bent out of shape!

Overall, it was a successful day, and an amazing two weeks. We can’t believe how fast this time went. The local Habitat affiliate hosted a farewell dinner for the 6 Care-A-Vanners who will be leaving tomorrow. The dinner was hosted at a local barn, with amazing food and fellowship. We arrived a little early to get a tour of the owners collection of assorted John Deere toys and toy farm equipment. Two full rooms were filled to the brim of old collectable items. It was evident that this was definitely a lifelong passion of his.

After the meal comes the hard part – saying goodbye to those who will be leaving tomorrow. We truly enjoyed working with everyone – it was an amazing team. God is good!